Dad came up from Tennessee to work on the plane last weekend. We did a decent amount of work even though it didn’t look like it.

- inspected the recently arrived wing kit and associated gear

- We trimmed and cleaned up the shorter elevator rib in front of the trim tab.

- Test fit trim actuator

- cut access for the trim actuator to connect the elevator to the trim tab.

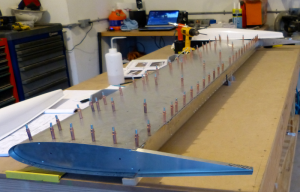

- Riveted the bottom of the elevator together leaving the center uncompleted per directions.

- Test fit the elevator to the horizontal stabilizer. Elevator operated smoothly.

- Layed out hinge and drilled holes in the elevator to attach the elevator to the horizontal stabilizer.

- Pops deburred the newly drilled holes and is ready for the next step

Thanks for the help pops!

Here are some pictures